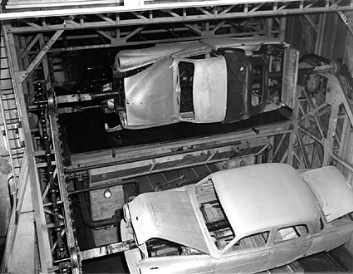

THE ROTODIP PROCESS

Two Austin 1800's

on the "skewer".

Photo Courtesy National

Archives Australia - A1200 - L54594

BMC use a process called electro-coating to supplement their basic Rotodip rust proofing treatment.

The Rotodip method

treated and painted complete car bodies. The electro-coating plant was

used to paint small components not able to be treated on the huge Rotodip

machine. The combined result provides complete rustproofing of all painted

components of BMC cars.

The electro-coating

installation cost $280,000 and was the first of its kind in Australia. It was in operation

since May 1966.

Electro-coating is

a similar process to electroplating. Metal is plated, rather than sprayed,

with paint to give uniform and complete coverage, even inside tubes

and other normally inaccessible areas.

Bodies for all Australian

made BMC's - Mini, Morris 1100 and Austin 1800 were all treated on the

$2 million Rotodip machine during manufacture. On this exclusive machine,

the unpainted bodyshell and doors were submerged and rotated in a series

of baths containing phosphates and primer. This treated and covered

every metal surface, both inside and out, to prevent the onset of rust.

The electro-coating

plant painted small parts, which could not be treated by the Rotodip

process. This included such parts as the fascia, or dashboard panel,

heater boxes, grille panels and numerous small sheet metal parts not

welded to the body itself.

Electro-coating was

a major advance in the technology of metal coating. It involved a dip

process in which paint is held in suspension by a liquid. The paint

is deposited on the metal component when an electric current passes

from an electrode to the vehicle, which acts as the other electrode.

Paint particles are attracted to the metal, coagulate and are deposited

until an even paint film covers the entire surface, including edges

and remote crevices, and all internal surfaces. When the paint film

reached a certain thickness it insulated the metal and prevented more

paint being deposited.

When deposited, the

paint is hard and cannot be removed.

Unlike spraying or

conventional non-handling dipping methods, electro-coating left no uncoated

areas in parts of complicated shapes. It also gave an even paint thickness

and virtually eliminated paint loss.

The Rotodip process

fully immersed and rotates each sedan body in a six-stage phosphating

machine, then took it through a drying-off oven, followed by a dip tank

of special rust inhibiting priming paint, and a primer baking oven.

All these processes were continuous and automatic.

To move through the

machine the unpainted car body was skewered on a long metal spit, which

had a sprocket at one end. The sprocket ran on a toothed rack, so that

the spit - and the body clamped to it - rotated as they moved.

The first tank contained

a heated alkali to remove oil and other contaminants. The second tank

contained a cold water rinse, and the third a hot water rinse, to make

sure the body was perfectly clean before it enterd the phosphating tank.

In the phosphating

section the 'skewered' body was lowered into various tanks while rotating.

At the same time high pressure jets sprayed the solution so that every

bare metal portion of the body was treated, both inside and out. Phosphating

is actually a conversion of the body steel surface so that if the paint

surface was damaged accidentally during use, corrosion would not spread.

It also acted as a bond between steel and paint.

The phosphating was

followed by a hot water rinse and then by a heated chromic acid rinse.

The body completed two slow revolutions in each tank. After phosphating,

the body was dried in an oven. It was then dipped and rotated in a 7,000

gallon tank of primer, remaining for 2.6 minutes. This meant that every

particle of bare metal received a coating of paint. Excess paint drained

away through special holes provided in body panels and other enclosed

parts. The painted body, still rotating, was baked in an oven for 30

minutes at 340 degrees Farenheit.