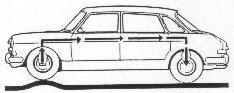

Tail rises in response

to upward movement of front wheels eliminating pitch.

Nose rises in response

to upward motion of rear wheels - no pitch.

|

|

HYDROLASTIC SUSPENSION

|

|

THE PRINCIPLE OF THE HYDROLASTIC SUSPENSION The outstanding

feature is its simplicity of operation. The front and rear Hydrolastic

displacers on each side of the car are inter-connected by a small bore

pipe. The system is hermetically sealed and therefore never needs any

further attention during the normal working life of the car. Each displacer

incorporates a rubber spring, and damping of the system is achieved by

rubber valves. So when a road wheel is deflected, fluid is displaced to

the corresponding suspension unit. In turn, it is raised in anticipation

of its wheel encountering the cause of its counterpart's deflection. The

rubber springs are only slightly brought into play and the car is freed

from any tendency to pitch, although full play is given to wheel movement,

producing a soft ride.

|

|

|

|

|

|

Tail rises in response

to upward movement of front wheels eliminating pitch.

|

Nose rises in response

to upward motion of rear wheels - no pitch.

|

|

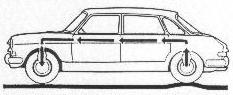

When front and rear wheels encounter a simultaneous deflection, the fluid suspension stiffens in response to the upward motion and, while acting as a damping medium, transfers the load to the rubber springs giving a controlled, vertical, but level motion to the car.

Suspension stiffens in response to upward motion of front and rear wheels, giving controlled, level, vertical movement. The restriction

of the fluid flow, imposed by the small bore piping, rises with the speed

of the car. The ride is therefore steadied at high speeds and softened

at low speeds a most satisfying condition hitherto only achieved by complex

and costly means.

The drawings

reproduced here are diagrammatic so that the principle of Hydrolastic

suspension is easily seen. In the actual car, the front suspension units

- seen below - are mounted horizontally across the engine bulkhead.

The displacer units can be easily seen in the housing.

General layout of the Hydrolastic suspension with the inter-connecting pipes. Not to be confused

with the Hydro-pneumatic suspension used by Citroen. Their system is not

a hermetically sealed pressure system like the Hydrolastic system used

by BMC.

Citroen use

a hydraulic pump system that raises and lowers the car to different heights.

A more superior system but more costly to manufacture and maintain. The

extraordinary thing about their Hydro-pneumatic system, is that it doesn't

use o-rings as seals. The pistons and bores are machined to incredible

tolerances (microns), making seals unnecessary.

|