The post-war car scene

To put these cars into perspective we need to recall the early post-war era.

Pre-war, most cars were of North American origin, Chevrolet, Ford, Dodge/Plymouth with a few Oldsmobiles, Pontiocs, Buicks and Willys. The largest sellers were sixes (except Ford V8) These cars were mostly identical to US models, the bodies generally made in Australia.

They survived well with minimum maintenance, poor fuel (even kerosene) and virtually no spare parts availability.

The typical prewar UK cars - Austin, Morris Standard, Ford or Hillman did not do as well in our environment with their smaller ground clearance, small engines and generally low power to weight ratio.

There is one UK make of car which must be mentioned as an exception to the above comments. Significantly, this was Vauxhall.

As well as producing a range of North American type vehicles in their VX, BX and GY models, in 1934 they introduced their 12 HP Light 6 followed by their 14 HP which was made pre and postwar. The larger 17.96 HP Velox was introduced post-war.

They had generally good ground clearance, roomy bodies, adequate suspension travel with independent front suspension (Dubonnet type). These cars were generally identical to those sold in UK. Obviously, the North American influence at Vauxhall had the effect on producing a car which was well accepted on the Australian market, both pre and post-war.

Post-war, Australia suffered a dollar crisis which made importation of North American vehicles and components very difficult. This gave importers and assemblers of cars from non-dollar areas such as UK and France a huge marketing opportunity. There was still a preference for North American cars but waiting lists of five to seven Years for these were not uncommon.

In comparison, you could buy an Austin 10, Hillman, Ford Prefect or Standard 12 virtually off the floor.

Local assembly of UK cars was quickly established by Nuffield in Sydney and Austin, Rootes and Standard in Melbourne also subcontractors Charles Hope in Brisbane and Pressed Metal Corporation in Sydney.

GMH and Ford were building their models from existing well-established plants.

By 1950, UK cars had 80 percent of the market with much more acceptable post-war designs such as the Standard Vanguard, Morris Oxford, Austin A40 and A70, Hillman Minx and Humber Hawk.

The conventional wisdom of the '40s and '50s was that, to be successful in Australia, a car had to have six cylinders the same is true today. The experts were vindicated when GMH announced its eagerly awaited, all Australian Holden in 1948 with a 21.6 HP engine!

Although they started off fairly slowly due to production constraints, they went from strength to strength, wiping the opposition in every department. The Hoiden had a roomy 6 seater body, good ground clearance, was easy to work on, gave up to 30 mpg, had lively performance, weighed only a ton, and the engine developed 60 HP. It had a simple but good steering column gear shift, considered essential if a car were to be considered modern.

BMC Merger

This led to the expansion of the Nuffield site to include Press Shop, Engine and Mechanical Production, Paint and Assembly shops and Product Engineering facilities. It was not until 1957 that the first cars were produced from the new facility.

It was apparent that little thought had been given as to what would be built in the Plant by UK Management, other than that it would be whatever UK were building at the time.

The Australian Product Engineering Department was not established until mid 1957 with R. L. (Bill) Abbott as Chief Product Engineer, R.W. (Bill) Serjeantson as Experimental Engineer and R. N. Fulford as Test Engineer - all ex GMH. J. M. Hamilton, Mechanical Engineer, came from the NSW Department of Road Transport, but had spent time at GMH.

The Wolseley 1500 (D.O.1059), Morris Major I (D.O.1058), Austin Lancer I (H56) were originally engineered at Cowley as a replacement for the Morris Minor, but weight got out of hand, making it necessary to use the B series engine to maintain performance. The result was a pleasant, low stressed, reasonable performing car with the internal size of a Minor.

Meanwhile the Minor remained in production here and in the UK selling in ever increasing numbers. Already engineered by UK was the first BMC car to be uniquely Australian, the Morris Major series II (D.O.1115) and Austin Lancer II released in 1959. This car had virtually the some floorpan as the series 1 but a larger boot and small tailfins. Although internal dimensions were slightly improved, it was still crammed by Australian standards. Performance was down with the inevitable increase in weight.

Meanwhile the Holden was still gaining ground, VW had come on to the market in 1954 and by 1959 dominated its class. Total UK origin cars had fallen to about 50%. Ford was still selling Zephyr, Consul and Prefect/Anglia, Standard the Vanguard and 8, and Rootes the Hillman Minx and Humber Super Snipe.

At BMC in 1959 we introduced the AD09 range, Austin A60 (UK-A55 mark II), Morris Oxford series V, and Wolseley 15160 - the Farina styled cars. Riley and MG versions were not built in Australia.

Australian B series 4 cylinder engine

Our original assessment was that the above cars would be greatly under-powered with the 1489 cc B series engine.

UK were adamant that this engine could not be made larger. Undaunted, the Australian design team, in a matter of weeks, had a 3" bore engine with "siamesed" cylinder bore casting up and running. The increase from 1489 to 1622cc was enough to make performance acceptable, and was used from first production.

The fact that UK followed our lead some 3 years later is a matter of history, and showed the "tail had indeed wagged the dog".

That the B series engine was capable of even further development in the original three main bearing form was demonstrated by UK in 1963 with the 1798cc MGB engine.

The 1959 model range

We now had a range of cars with contemporary styling, reasonable performance, reasonable to high standards of ride and comfort, good economy, and reasonable price.

We had the market covered, we thought, with the Morris Minor 1000, Austin A40 Farina, Morris Major II, Austin Lancer II, Austin A60, Morris Oxford V, and Wolseley 15/60, all locally assembled with a very high Australian content.

But where were the buyers? Off buying Holdens and VW!

Our market share was slowly diminishing. A new threat was looming with Ford tooling up to make the Falcon in Australia.

The Australian B series six cylinder engine

Australian BMC Management took the view that, if we were to protect the Corporation's investment in Australia, we would have to enter the light 6 market, which was expected to account for about 50% of total sales and rising.

The expected impact of Falcon was that they would account for 20% of total sales, much of which would be at our expense.

UK Management agreed to the need for a light 6 but decreed that it had to be fitted to the existing body as no money was available to undertake a restyling exercise so soon in the life of the Farina era - which they expected to have at least a ten-year life.

A crash program was put in place to develop a 6 cyl. version of the B series engine. The design had to be compatible with the existing cylinder block machining facility at Zetland so that both 4 and 6 cyl blocks could be machined on the same line. This was achieved at a cost of £288,000. Total tooling cost for the ADO 40 (Freeway and Wolseley 24/80) introduction was £535,000. Because insufficient facilities existed in Australia to develop a project of this magnitude, UK elected to do it there.

Mechanical engineer John Hamilton was appointed Project Engineer, with Graham Hardy as Body Engineer. They spent about six months in UK during 1960, ensuring Australian requirements were met.

It was obvious that UK had already done work on a 6 cyl. version.

The Australians had to talk very loudly to get the UK to change the bore size from 2 7/8" to 3"!! Much initial work was done on 2 7/8" bore engines and indeed the first 2 prototype cars to come from UK in 1960 had 2 7/8" bore engines.

Australian Repco pistons were sent to UK for incorporation in "proper" prototype engines.

Australian 1960s models

Other significant body and chassis changes were made including lengthening the wheelbase by 1" achieved by moving the rear axle back on the springs. This allowed the rear wheel arch to be reshaped to improve rear seat comfort.

The front suspension cross member was reinforced internally and rubber mounted to reduce road and engine noise and vibration being transmitted to the body. The rear axle was rubber mounted to improve NVH. The car was built on the station wagon floorpan and the track was increased by 2" for better stability.

The cars as released in May 1962 had a stylish, purposeful look, and outperformed both Holden and Falcon but not the recently released Chrysler Valiant with its 145 HP six.

The cars were well received by the motoring press, particularly the Wolseley 24/80 which was recognized as particularly good value for money. Indeed it was the forerunner of upmarket versions of standard models such as Holden Premier, Falcon Futura and Valiant Regal following soon after.

Release day prices were:

Freeway sedan £1130, Wolseley 24/80 sedan £1225, Holden Special sedan £1111, Falcon Deluxe sedan £1149, Valiant sedan £1239.

Despite the fact we offered a competitive range of vehicles, our market share in the 6 cyl. range was insignificant and, in general we lost ground to the superior marketing powers of GMH, Ford and Chrysler.

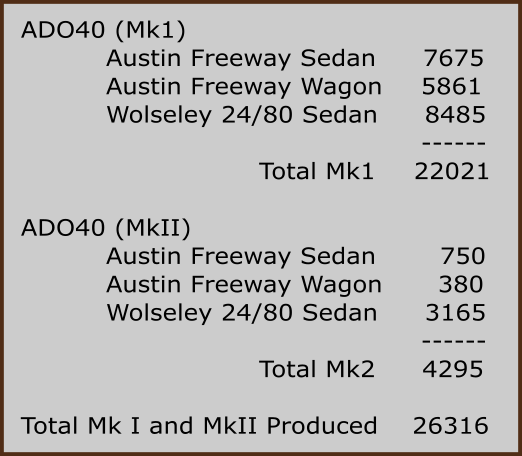

Eventually sales of Freeway faded away, although 24/80 remained strong right to the end. Production ceased in September 1965 after some 27,000 cars had been built.

The Corporation entered the front wheel drive era in 1961 with the Mini, 1964 with 1100, and 1965 with the 1800. The FWD car satisfied a different niche in the market, and for a time, the Australian Company enjoyed a long-awaited period of prosperity.

(Article written by Roger Foy who worked in the BMC Experimental Department from 1957 to 1974. Article reproduced from the BMC Leyland Australia Heritage Group March 2001 Newsletter.)